The Only Guide to Architectural Panels

Table of ContentsGetting My Kawneer Spandrel Panel Metal Spandrel To WorkSome Known Details About Opaque Spandrel Panels Rumored Buzz on Nhbc Spandrel PanelsThe Best Strategy To Use For Architectural PanelsInsulated Panels for Dummies

These systems often include gaskets that are placed in between the stress bar as well as mullions and function as thermal breaks and also aid with acoustic isolation. These systems require unique care in design as well as construction to ensure connection of the gaskets at horizontal as well as vertical transitions. Gaskets are also made use of to cushion the glass on the exterior and interior faces of the glass.There is usually a void in the gasket at the edges after shrinking happens. With a correctly designed system the water that enters the system at the gasket edges will certainly weep out through the snap cover weep openings. To alleviate shrinking of gaskets back from the corners making use of vulcanized corners as well as diagonally reduced splices are recommended.

At the curtain wall surface border, maintaining connection of the air barrier decreases air flows around the drape wall surface. Assimilation of boundary flashings assists make certain watertight efficiency of the curtain wall and its connection to nearby wall surface components. Correct positioning of insulation at the curtain wall perimeter decreases power loss as well as prospective condensation issues.

The spandrel area is generally not warmed, therefore the indoor setting does not heat the mullions and balance out the movement of the chilly temperature levels deep into the wall surface. In the vision area the interior warm aids to alleviate the cool and protects against condensation. Because of this, do not protect between the indoor part of mullions and also adjacent wall building either.

Facts About Spandrel Panel Definition Revealed

Back pans supply a second line of protection versus water seepage for areas of the curtain wall that are not visible from the inside as well as are hard to accessibility. Water seepage in opaque areas can proceed for prolonged durations of time causing significant damage prior to being detected. Back pans additionally are to be liked over foil vapor retarders in high efficiency and humidified structures as convection currents short-circuiting the insulation can create condensation, wetting and inevitably failure of these spandrel locations.

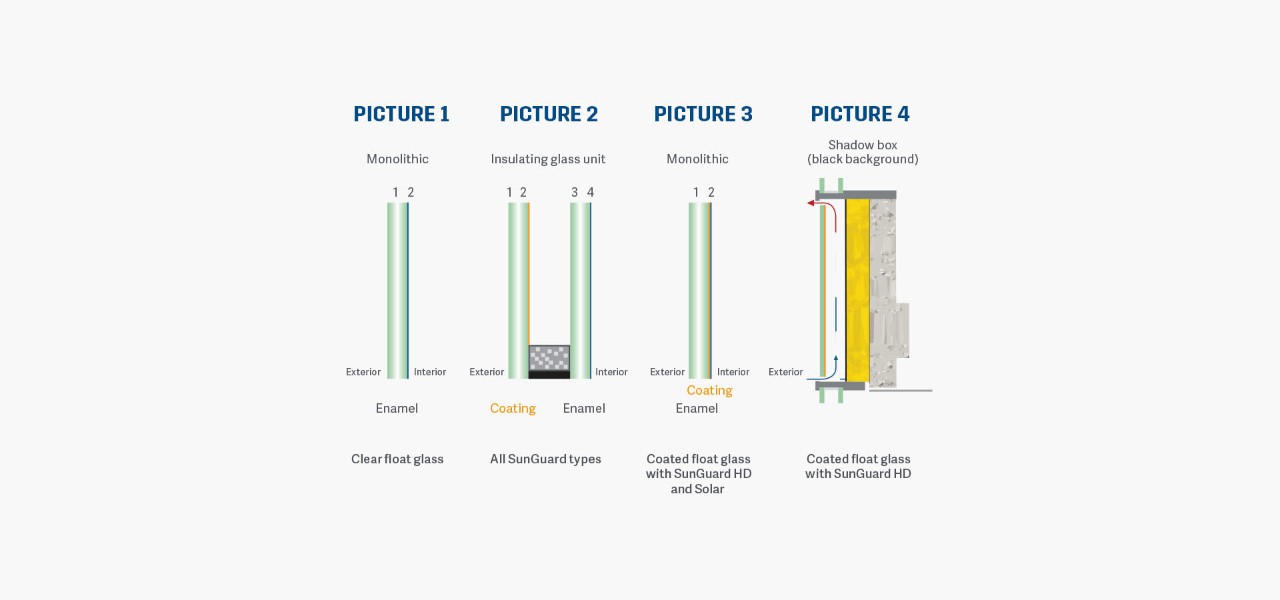

The steel sheet ought to be at least two inches behind the glass as well as may be painted or developed to produce a structure, but reflective surfaces include one of the most aesthetic depth to the wall surface. Insulation needs to also be installed behind the shadow box if interior finishes protect against area air from calling this area.

For that reason the links to secure the curtain wall should be designed to permit differential activity while withstanding the tons applied. In stick-framed light weight aluminum drape wall surface, upright mullions commonly run past two floors, with a mixed gravity/lateral anchor at one floor and also a lateral support just at the other. The splice between the upright mullions will certainly additionally be developed to permit vertical motion while offering side resistance.

Keep in mind that this movement a little misshapes the anchors at the upright mullions. Specific units of glass must fit the activity of the bordering aluminum structure by sliding along glazing gaskets, distorting the gaskets or a combination of both. The motion of the glass within the framework as well as the activity forced in the supports often tend to cause added anxieties right into a stick framed system.

The Main Principles Of Nhbc Spandrel Panels

Laboratory-tested fire rated assemblies might be called for in unsprinklered structures by some codes as Perimeter Fire Containment Systems when the floor assemblies are called for to be fire-resistance ranked. The rankings of the Perimeter Fire Containment System need to amount to or higher than the flooring rating. These systems provide confidence that the products used for border control stay in location for the defined duration of the needed ranking in a fire event.

Curtain wall surfaces and perimeter sealers call for maintenance to optimize the service life of the curtain wall surfaces. Boundary sealants, appropriately created as webpage well as installed, have a common life span of 10 to 15 years although violations are likely from the first day. Removal as well as replacement of boundary sealers requires meticulous surface area preparation and also correct describing.

The most effective method for sustainability of drape wall surfaces is to use great design techniques to ensure the toughness (maximum service life) of the installation and also to utilize systems that have a good thermal break and also high R-value (worths as high as R-7 are possible with triple-glazed systems). Likewise, the usage of low-e and spectrally careful glass finishes can considerably reduce energy lots and boost comfort near to the wall surface.

Curtain wall design need to begin with the assumption that outside glazing seals, boundary sealant joints as well as drape wall surface sills will leak (opaque spandrel panels). The adhering to summarizes suggested attributes: Select frames with wept glazing and pocket sills sloped to the exterior to collect water that penetrates the glazing and drain it to the exterior.

Our Spandrel Panel Window Ideas

Use as lots of 1/4-inch by 2-inch ports as required for pressure-equalized systems. Design the drain system to take care of condensation as well as rainfall. Curtain wall boundaries need to have flashings (sill, jambs as well as head) that are sealed to the air as well as water obstacle at surrounding wall surfaces. Slope head as well as sill flashings to the outside to promote drain.

Polishing Approaches as well as Their Effect on Efficiency Pressure Plate Glazing: In this system the glass and also infill panels are set up from the exterior, normally versus completely dry gaskets. The outer layer of gaskets is set up as well as the gaskets are pressed against the glass by navigate to this website the torque put on bolts safeguarding a constant pressure plate.

The structure is fixed and also exterior completely dry gaskets are set up. Commonly only the top inside mullion has a removable stop. The glass system is glided into a deep glazing pocket on one jamb much enough to allow getting rid of the opposite jamb and is after that glided back into the opposite glazing pocket and after that dropped into the sill glazing pocket.

Some Known Factual Statements About Roof Spandrel Panels

Occasionally this approach is called "wiggle" or "shake" glazing as a result of the control necessary to get the glass right into place. Efficiency find more information is slightly decreased because dry steel to steel joints happen at the ends of the removable stop at a point that need to effectively be air and watertight. Wet sealant heel grains will certainly boost efficiency and also some systems consist of an additional gasket to create an air barrier seal.

Structural Silicone Glazing: In this system the glass or infill system is adhered to the framework with a bead of silicone. External silicone weather seals supplement the architectural seal. Unitized systems are regularly structural silicone polished, specifically if four-side SSG is preferred. Two-sided SSG, with pressure plate glazing or wiggle glazing on the various other two sides serves to be field installed (insulated spandrel panel detail).

The CRF does not give details regarding cold places that might result in neighborhood condensation. Jobs for which condensation control is an important issue, such as high indoor humidity structures, need project-specific limited element evaluation thermal modeling using software program such as THERM. Cautious evaluation and modeling of indoor conditions is needed to accurately approximate the indoor temperature level of the air at the within surfaces of the glass and also structure.